Tool & Diemaking Program Details

Questions? Contact Us!

Mark Rosenberry

Program Chair

merosenberry@dmacc.edu

515-964-6452

Need Help Getting Started?

DMACC

Admissions Office

admissions@dmacc.edu

515-965-7337

A career in the tooling industry, ranging from interacting with CNC machining equipment

and performing precision handwork to repairing damaged machine parts and more.

Make the fixtures, dies, molds, tooling, gages and more that are used to create the products we use every day. Become a skilled technician with hands-on training to learn the diemaking process from manual tooling to computer numerically controlled (CNC). The DMACC Tool and Diemaking program prepares graduates to be skilled professionals in this high-demand career.

Program Entry Requirements

Machinist Technology

Complete an application, satisfy the assessment requirement and attend any required information or registration session. Students start fall term.

Diemaking

Complete an application, satisfy the assessment requirement and attend any required information or registration session. Submit proof of Machinist Technology Diploma or equivalent. Students start fall term.

Graduation Requirements

To earn a Job Shop Maintenance or Diemaking diploma, or Tool and Diemaking AAS degree, a student must complete all course work as prescribed and maintain a 2.0 grade point average.

Job Information

- Make dies, metal forms and tools, as well as guiding and holding devices which are used in the mass production of metal and plastic parts.

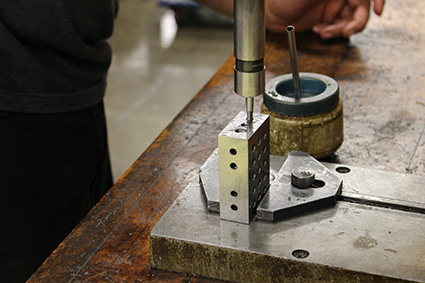

- Spend time doing precision handwork on dies such as sanding, filing, scraping and polishing parts of the dies.

- Use almost every kind of machine tool and precision-measuring instrument.

- Repair gauges, jogs, fixtures, and dies which may be worn or damaged.

- Loading...Tool & Diemaking, AAS

Skills and Abilities Needed

- Apply math skills in specific machine setups and operations.

- Organize your work, planning each step of the job from beginning to end.

- Maintain a steady hand for precise movements and use your eyes for close work for

long periods of time.

Be able to lift 25-50 pounds. - Demonstrate imagination and creativity on the various machine setups and operations.

- Demonstrate a positive attitude and work closely with others.

- Be able to detect differences among similar colors.

Other Considerations

- Work is mentally and physically tiring because you will have to concentrate and be alert for extended periods of time.

- To be a journeyman machinist, you will need two or three years of on-the-job apprenticeship experience.

- There is danger of accidents due to the high-powered, fast moving machine parts.

- Most of the work will be done in a standing position.

Here is the equipment you'll be working on in the Tool & Die program.

HAAS VF1 Vertical Machining Center (2)

HAAS Control Panel Simulators (7)

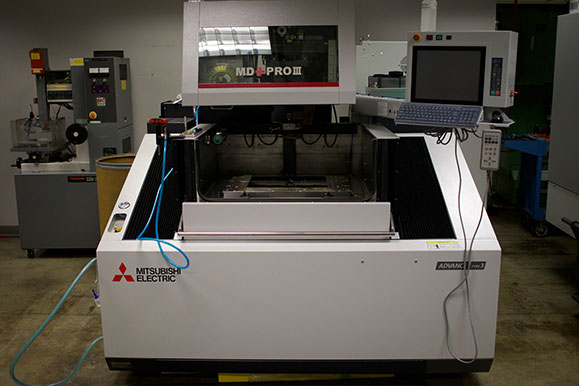

Mitsubishi Wire EDM

Charmilles Conventional CDM

Engel Injection Mold Machine

Manual Vertical Milling Machines (15)

Manual Lathe Machines

75 ton Heim Punch Press

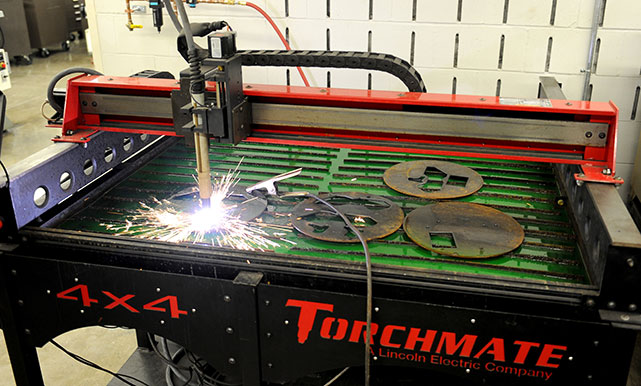

Torchmate CNC Plasma Cutter

Surface Grinders (12)

HAAS Lathe CNC (3)

Zeiss Duramax CMM

HAAS EC 300

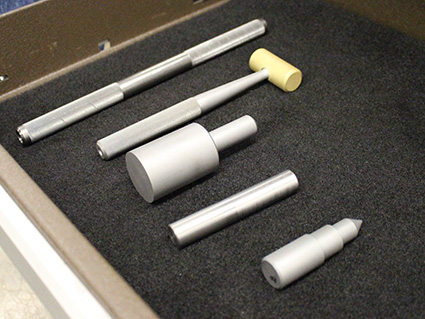

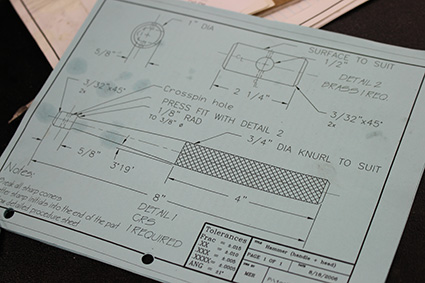

1st Year Projects

During the first year of the program, students learn the basics in manual mill and lathe operations and print reading. They move in to CNC mill and lathe in the first summer term.

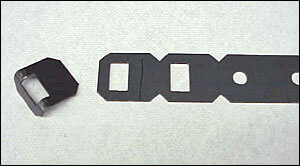

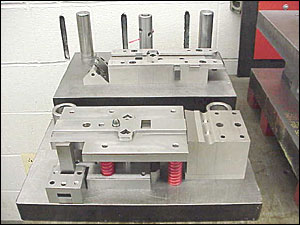

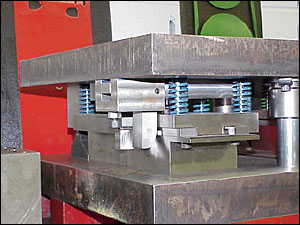

2nd Year Projects - Building Dies and Molds

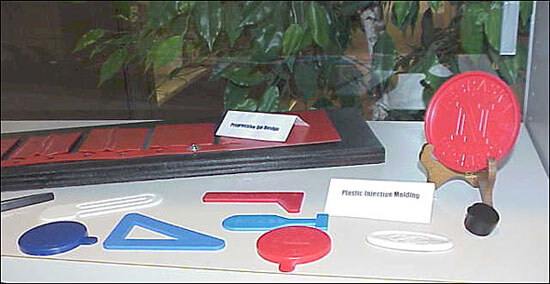

The second part of the Second year class is to build a progressive die that results in a manufactured part. The example shown here is for the lid of a washing machine.

Building Molds

Student build molds and mold machine. Below are some examples of material that comes from molds and the computerized machine that uses the molds to make items.

Building Injection Molds

Students build plastic injection molds. Below are some examples of piece parts that comes from molds and the mold machine that uses the injection molds to make the products.